SuperFoam pilots iVolt at their Ruiru Factories and reap the rewards of Voltage optimization

Superfoam has always had its roots in technological advances and has the commitment to invest and develop the best Manufacturing equipment and processes.

Mombasa-Kenya: 19 July, 2016 – Superfoam has always had its roots in technological advances and has the commitment to invest and develop the best Manufacturing equipment and processes. Like most, they were facing huge efficiency losses due to prominent power problems, causing frequent damage to their production line equipment. Following a sit down with Superfoam’s Energy auditors in search for a solution for protection & energy saving, The IVOLT system was proposed.

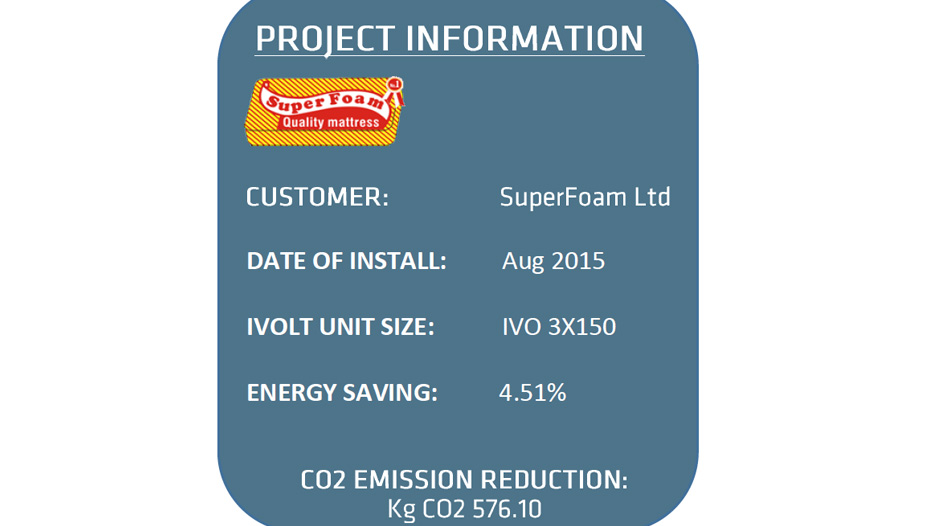

The iVolt looks like a win win for us, not only have we had no break downs related to power fluctuations on the foaming lines, early indications are showing savings of up to 4.51%

Imran Khan Customer Support Manager

Superfoam has always had its roots in technological advances and has the commitment to invest and develop the best Manufacturing equipment and processes. Like most, they were facing huge efficiency losses due to prominent power problems, causing frequent damage to their production line equipment. Following a sit down with Superfoam’s Energy auditors in search for a solution for protection & energy saving, The IVOLT system was proposed.

The voltage optimisation technology was chosen over other systems on the market not only because it’s a variable reduction system offering up to 30% more savings than fixed reduction units, but because it offers an integrated Intelligent Real Time (IRT TM) energy monitor. This device is capable of accurately tracking the savings being achieved in real time.

Currently, Superfoam’s production line is running efficiently, on clean optimised power, achieving 4.51% energy saving. On the basis of success of this project, iVolt are currently looking in to projects for the assembly lines as part of the factories pursuit to reduce energy consumption and adhere to ERC regulations, and efficiently run the manufacturing process despite frequent power; Improving power protection and energy saving. The iVolt once fitted has a minimum service life of 25 years, making for an excellent long term net savings at the factory. The ongoing costs and maintenance requirements of the iVolt are virtually zero.

With a full 15 year parts and labour warranty offered, SuperFoam factory managers can be confident for an ongoing I power protection and energy saving.

|

CONTACT US |

|

Sollatek Kenya |