Rossmann Group – A Leading Manufacturer of Packaging Solutions in Europe and Africa

The Rossmann Group started its activities in 1922, by establishing a packaging plant in Strasbourg. Today, it has become the leading French producer of corrugated packaging solutions, with an annual output of 370 000 tonnes. It also manufactures paper, at a rate of 210,000 tonnes per year. The Rossmann Group employs nearly 3,000 people within its 27 industrial sites in Europe and Africa.

ABOUT THE GROUP

HISTORY

• 1888: Frances’s first corrugated cardboard factory established in Exideuil.

• 1922: Lucien ROSSMANN established a flat cardboard factory in Strasbourg.

• 1938: The company started manufacturing corrugated cardboard at the Saint Croix aux Mines site in France.

• 1958: Corrugated cardboard factory establish in La Vancelle, France. Sainte Croix site starts specializing in paper manufacturing.

• 1964: Bernard ROSSMANN joins the family business and becomes company chairman in 1970.

• 1979: ROSSMANN SAS takes control of SOFPO, a corrugated cardboard factory in Exideuil.

• 1985: Bernard ROSSMANN becomes chairman of the CHARFA Group. He acquires control of the corrugated cardboard sector including the companies CELTA, SICAL and VALSCIUS in 1988.

The ROSSMANN Group begins its international expansion:

• SONACO (Ivory Coast) taken over in 1986

• SONACEB (Burkina Faso) created in 1987

• ROMCARTON (Romania) taken over in 1990

• AMBRO (Romania) taken over in 1996

• RAWIBOX (Poland) taken over in 1997

• KADEM (Spain) taken over in 1997

• SERVIBOX (Belgium) created in 1997

• SICAL floated on unlisted securities market in 1998

• SONAPACK (Ghana) created in 2007

KEY FIGURES

• Corrugated board: 370 000 tons (yearly output), capacity of 500 000 tons

• Container board: 210 000 tons (yearly output), capacity of 300 000 tons

• Turnover in 2015: 483 millions €

• Employees: 3 000 (500 of which are based in Africa)

• An international company: 27 production sites (24 in Europe and 3 in Africa)

BUSINESS

CORRUGATED BOARD

• Box plants – The Group is the main independent packaging manufacturer in Europe and Africa with a production capacity of 500 000 tons. As a pioneer in Europe, with strong experience of materials and expertise of customers needs, its know-how is recognised. Its range of machines allows it to offer all various kinds of printed packaging.

Sheet plants – 10 sheet plants in Western Europe and 1 in Burkina Faso, manufacturing taylor-made packaging to serve their own clients or to offer a complementary range to their box plants.

CONTAINER BOARD

Papers – With a yearly capacity of 300 000 tons, Rossmann’s paper mills feed all its corrugators. The Group only manufactures papers made of recycled fibers, mainly:

– schrenz and brown test liners from 100 to 220 gsm

– medium from 90 to 160 gsm

RECYCLING

Reshuffle your packaging – SOREST, OCC collector born in 1974, collect, recycle and reuse 60 000 tons of waste papers for Rossmann’s paper mills. SOREST’s proximity helps local clients to recycle their waste and match legal obligations.

DISTRIPACKAGING

The Rossmann Group has a whole team at its customers’ disposal to meet their requirements. A distributor to help them. A complete solution with:

• boxes

• adhesives

• strips

• stretch film

• bubble film

• corner post

• pallets

• boxes and gift boxes for Post Office mailing

EPS

SICAL, expert in expanded material moulding, converts EPS and PP, with a strong experience in packaging crates for sea food, meat and ice. Its know-how also spreads out to pharmaceuticals with respect of the cold chain, insulating material for construction industry, specific wedges and protections for industry. With its 30 lines the company reaches a yearly output of 1 200 tons.

About the SICAL box plant:

Address: 69 rue du docteur Pontier

City: 62380 LUMBRES

Country: France

Contact: Click here

Tel.: +33 321 386 000

Capacity: 130 000 000 sqm.

Business: Design production and manufacture of corrugated board packaging.

Products:

• RSC

• Die-cuts

• Crashlock bottom

• 4 & 6 glued corners

• Containers, octabins, box

• All printings

ABOUT THE ROSSMANN GROUP:

WEBSITE: www.rossmann.com

BIOGRAPHY:

• Jérôme Meplon – Biographie

INTERVIEWS:

• SONACO : Un Leader du Secteur des Emballages et du Carton en Afrique de l’Ouest

• SONACO: A Leading Manufacturer of Packaging Solutions in West Africa

VIDEOS:

• Industrie des Emballages et du Carton en Côte d’Ivoire et en Afrique de l’Ouest

• Groupe Rossmann : Le Spécialiste de l’Emballage en Carton Ondulé

• Jérôme Meplon : Développement de la Côte d’Ivoire et de l’Afrique

• SONACO : De la Caisse Américaine aux Emballages Mécanisables, Préformés et Antivols

• Secteur des Emballages en Côte d’Ivoire : Avantages Concurrentiels de SONACO

• Responsabilité Sociétale de SONACO et du Groupe Rossmann

• Développement de SONACO et du Groupe Rossmann en Afrique

SEGMENTS

AGRO FOOD STUFF

With a strong presence in agro food stuff business (45% of its revenue), the Rossmann Group has developed suitable know-how adapted to specific needs in terms of creativity, reactivity, quality and safety. From food contact to POS, displays, e-commerce, shelf-ready packaging, HQPP or digital printing, the Group is ready to support all types of projects.

• Dairy products – The Rossmann Group is present in the dairy products segment. Mindful to its clients needs, the Group pays high attention and care on board quality, runnability on packaging machines, and OTIF. Regarding corrugated board crates, boxes or specific packaging, for products standing the load partially or not, the Group always meets its clients’ expectations.

• Confectionnary – Packaging is designed to protect, inform and carry ; it is also often a support to enhance products’ attraction in shelves or points of sale (POS). Rossmann offers a full range of capability in terms of design, qualities, printing and cuts to match clients’ expectations.

• Bakery – Packaging requirements are linked to the products and market: performance, productivity, hygiene, convenience and a liable supplier efficient at low cost. Rossmann has suitable answer from design to end of lines mechanisation where it advises its customers.

• Beverages – Packaging reflects brands’ image, so it is important to take great care of manufacturing and printing. The Group is perfectly skilled and equipped to face such challenges. Productivity is linked to mechanisation. Rossmann’s know-how is recognized, and the Group acts as an independent advisor and recommends efficient solutions.

• Meat, deli corner, fish – The right packaging is the one responding to companies’ needs. Logistics and retail require rigour to ensure sustainable performance all year long, in fridges and frozen trucks as well. Present in the market for almost 100 years, Rossmann has the know-how to meet clients’ needs.

FAST MOVING CONSUMER GOODS (FMCG)

Rossmann’s plants are equipped to cover wide ranges of packaging types, formats, quantities, printings, etc., for semi-durable or durable goods and products.

INDUSTRY

The Rossmann Group has been accompanying the development of industrial products for more than 100 years. Packaging is a function, and the Group analyses it in terms of total industrial cost. Its teams are in the state of the art to help clients find the best leverage between their needs and packaging costs.

• Fabric – Textile companies often use large box dimensions to protect their products and optimise logistics costs. Quantities are variable and require supplier agility. Rossmann’s range of formats and quantities can meet clients’ expectations.

• Furniture – For Rossmann, the main feature of the furniture segment is based upon multiple references requiring specific equipment to face both large formats and small runs. Historically present in this segment, the Group is well equipped in that respect and ready to serve furniture companies.

• Automotive – The Rossmann Group is historically among the European leaders in automotive industry packaging, respecting its specific norms and encountering suitable equipment to match clients’ needs.

• Chemical – The chemical segment requires strong and practical packaging respecting specific norms (dangerous goods, etc.). Rossmann offers a wide range of heavy board qualities and suitable certifications to meet clients’ expectations.

• Pharmaceutical-Cosmetics – Present on this segment for more than 50 years, Rossmann’s packaging responds to resistance, machinability and liability criteria required by customers.

LOGISTICS

Logistics packaging trends follow new buying modes: internet, e-business, drive, etc. Often banalised, they shall mainly be available on demand. Standards or customized, manual or mechanized, however the rule is simple: clients cannot wait. Rossmann’s R&D teams boost their database day after day, gathering various packaging solutions.

PRODUCTS

MECHANIZED PACKAGING

There are different types of mechanized packaging designs (RSC, WA, trays, crates, 1-2 or 3 pieces SRP, etc.). Formation, loading and closing operations can be operated on monobloc or modular machines, depending on products and packaging type. Therefore it is important to analyse customers’ products, current and future needs, their environment, and to share expertise and facilitate making choices.

• Wraps around – A wrap around is a flat packaging formed around products, therefore usually designed for products standing the load. It runs on a compact machine gathering 3 functions: formation, loading and closing. This type of packaging requires constant quality and good knowledge of mechanization constraints. Rossmann’s mechanization experts are at clients’ disposal to help them optimize their end of lines.

• RSC – Born in 1880, RSC represent today almost 40% of market needs. RSC can be mechanized, with handles, perforations, tear tape, pre-cuts for easy opening, easy shelving and easy flattening. With HQPP RSC, companies can carry their image along the supply chain. The Rossmann Group is perfectly equipped to supply state of the art RSC, suitable for mechanization, highlighting customers’ image with high quality printing.

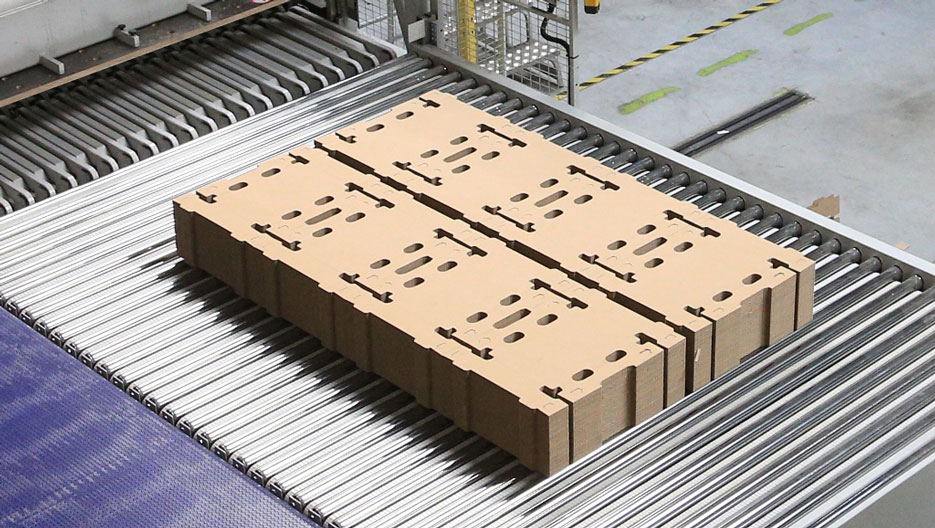

• Trays – Trays are flat die-cuts formed manually or mechanically, usually at high speed, in cavities or around the products. They require accuracy, constant quality, perfect palettization, and clean printing to enhance products’ attraction in shelves.

SHELF READY PACKAGING (SRP)

Usually made of 1 of 2 pieces of board, SRP gather both logistics and presentation in shelve functions. They require special attention as quality of manufacturing (pre-cuts, assembly, printing) will be evaluated by consumers. The Rossmann Group accompanies clients’ SRP from launch to industrial runs, with suitable means in terms of pre-cuts and printing technologies according to their needs.

PACKAGING FOR INDUSTRY

The Rossmann Group has been accompanying the development of industrial products for more than 100 years. Packaging is a function, and the Group analyses it in terms of total industrial cost. Its teams are in the state of the art to help clients find the best leverage between their needs and packaging costs.

• Octabins – Octabins are designed to contain more than one metric ton of goods. Their octagonal shape improve stacking strength while reducing bulging pressure. Options: reinforcing tape, crash lock bottom (Rosstainer), printing, etc.

• Kits and Box pallets – Such packaging is designed for transportation of heavy and large goods. They are composed of several parts delivered flat on pallets. Assembly is simple and fast.

• Fan folding – This product consist of a continuous corrugated board sheet folded in “accordeon” on pallet. Suitable to:

– pack pieces of differents formats (additional folds available)

– design tailor-made packaging (additional equipment)

• Celtapyre – Fireproofed board classified M1/CSTB, allowing perfect protection for welding or maintenance works. This product is availlable fan folded on pallet (60 meters length), ready to be cut at your dimensions. Light and recyclable, this product is easy to carry to worksites.

• Partitions and Wedges – Rossmann manufactures partitions, wedges, and protection parts in corrugated board or moulded EPS-PP.

CRATES

Corrugated board crates match key criteria of protection, logistics and presentation. Manual or mechanized, standard or specific to the products, they stand high level of constraints. A perfect definition of the needs and regular manufacturing are required to meet expectations. The Rossmann Group teams are qualified to deliver a state of the art job, optimising packaging behaviour.

E-BUSINESS

E-Business encounters steadily growth requiring:

– adapted packaging design (packaging on demand or standardization)

– flexibility on quantities and lead times

– secured quality, representative of the companies

Rossmann is present in the e-business segment through efficient coordination between its box plants and sheet plants, essential to guaranty top service.

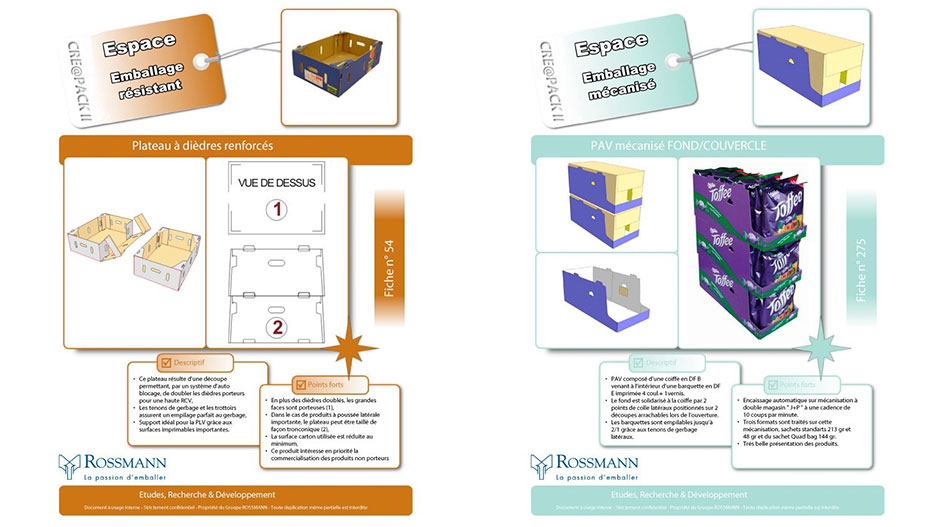

BOX AND P.O.S.

Points of Sale packaging are designed to highlight products and attract consumers. Over 150 designs are at clients’ disposal on the CRE@PACK® computerized library. Tailor-made, multi-material, they are printed flexo, screen, offset or digital to enhance eye catching.

INNOVATION

STRENGTH FOR CREATION

R&D – Packaging is much more than a commodity and total packaging cost is a fundamental notion. Rossmann’s R&D teams gather 50 experts, decentralised and mindful of clients needs. Their job: to optimize packagings and support customers in their mechanization projects.

CREAPACK

Designed by Rossmann’s R&D teams, CRE@PACK® is a computerized and comprehensive data base embracing the Group’s creations, sorted by product families, facilitating group know-how and expertise benchmark. Link to demo (French version) with username “demo” and password “demo”.

ROSSMANN’S COMMITMENT

• The client is the priority.

• The Group is built over human, ethics and environmental values.

• Rossmann’s financial independence is essential.

• The logotype represents family spirit, strength and energy.

SOCIAL

At Rossmann Group, people are always the core concern.

Rossmann’s plants have adopted a policy to upgrade individuals skills based on:

• training plans for new employees

• continuous training

• multiple skills

Employees support corporate values on the ground.

The Group’s focus is to recruit, develop, train, retain and support, to address key issues of today and tomorrow.

ETHICS

The Rossmann Group, respectful of its clients, employees, partners and environment, has built up its development over 4 core values:

• human respect and tolerance

• care for environment and safety

• performance-driven culture

• honesty and loyalty

They are formalized in a 3 chapters chart:

• ethical and professional values

• core principals related to values, rules and laws

• Rossmann Group commitments to its shareholders, clients, suppliers and employees

SAFETY & HIGIENE

Rossmann’s policy :

• to preserve the safety of its people, employees and visitors

• to preserve infrastructures and properties

Rossmann’s facilities match this will through :

• continuous improvement policy integrated into quality system management

• commitment to the “health and safety at work” certification

• implementation of adapted and responsible hygiene and cleanliness approach

QUALITY

Rossmann’s targets are clear :

• Clients satisfaction through products and contractual commitments fulfilling

• Innovation, creation and support capability for goods and services

• Everybody’s support and constant compliance to safety, hygiene and environment rules

SONAPACK – GHANA

PROFILE

SONAPACK Ghana Limited is a leading light in the corrugated cardboard carton industry in Ghana. The company is a subsidiary of the Rossmann Group, the number one French corrugated cardboard company in Europe and Africa, which has been owned and operated by the Rossmann family for close to a hundred years now.

Currently located in a large modern facility in the Tema Industrial Area, SONAPACK is able to service the needs of even the largest consumers of packaging materials. Its success is built on a foundation of manufacturing quality corrugated cardboard products at competitive prices, delivered on time, to a diverse range of customers.

SONAPACK began fabricating in Tema after its incorporation in 2007. By dint of hard work by management and staff, the business grew rapidly. With managed growth over a 2 year period, SONAPACK outgrew this site, and the search for a new home commenced, resulting in the purchase of a bigger factory and improved machinery. With this move, the company could now compete effectively in the market and manufacture its own corrugated cardboard from scratch. 2009 was the dawn of a new era for SONAPACK, following the expansion and relocation to the new and extensive manufacturing and warehousing facility.

The Rossmann Group embarked on a large capital investment project, installing a state of the art corrugator and modern converting equipment and quality assurance systems. The investment was not limited to equipment. The Rossmann Group employed some of the best brains in the packaging industry to add value and depth to the talent and experience of the management team.

Today, SONAPACK stands tall in the Ghanaian corrugated cardboard market as a truly formidable alternative. Customers have a real choice for all their packaging needs. SONAPACK is committed to continued investment and growth underpinned by the Rossmann Group’s passion for packaging.

About SONAPACK Ghana Limited:

Address: Heavy Indutrial Area, PMB Community One Tema

City: Tema

Country: Ghana

Contact: Click here

Tel.: (+233) 303 213 353

Capacity: 30 000 000 sqm.

Business: Design production and manufacture of corrugated board packaging.

Products:

• RSC

• Die-cuts

• Crashlock bottom

• 4 & 6 glued corners

• Containers, octabins, box

• All printings

SONACO – IVORY COAST

PROFILE

• Coming soon

About SONACO:

Address: Zone industrielle de Yopougon – 01 BP 1119

City: Abidjan

Country: Ivory Coast

Contact: Click here

Tel.: (+225) 23 51 52 00

Capacity: 100 000 000 sqm.

Business: Design production and manufacture of corrugated board packaging.

Products:

• RSC

• Die-cuts

• Crashlock bottom

• 4 & 6 glued corners

• Containers, octabins, box

• All printings

SONACEB – BURKINA FASO

PROFILE

• Coming soon

About SONACEB:

Address: ZI 1534 Route de Banfora – 01 BP 3125

City: Bobo Dioulasso 01

Country: Burkina Faso

Contact: Click here

Tel.: (+226) 20 97 03 30

Business: Design production and manufacture of corrugated board packaging.

Products:

• RSC

• Die-cuts

• Crashlock bottom

• 4 & 6 glued corners

• Containers, octabins, box

• All printings