Leading pipes and valves manufacturing company in Saudi Arabia: interview with Saudi Pipe Systems Co.

In 1994, we saw that the infrastructure in Saudi Arabia needed a lot of development; therefore, we built our own company to capitalize on this opportunity.

Interview with Mohammed Al Hammouri, Deputy GM of Saudi Pipe Systems Co.

How easy is it to do business in Saudi Arabia?

Saudi Arabia is one of the best places to do business because it is a big country and resources are plentiful. The cost of energy is low compared to other countries. I think doing business in Saudi Arabia is relatively easy.

Where do you see some of the investment opportunities?

In the infrastructure sector like pipelines for water and for sewage which is actually our field. Saudi Arabia needs a lot of work in development of infrastructure.

We understand the manufacturing industry development is a government priority and the sector has been growing faster than the oil related sectors.

The government is supporting the manufacturing industry and the industrial development of the country.

From the private sector perspective do you think mega projects and increased project spending is the right way forward?

In 1994, we saw that the infrastructure in Saudi Arabia needed a lot of development; therefore, we built our own company to capitalize on this opportunity.

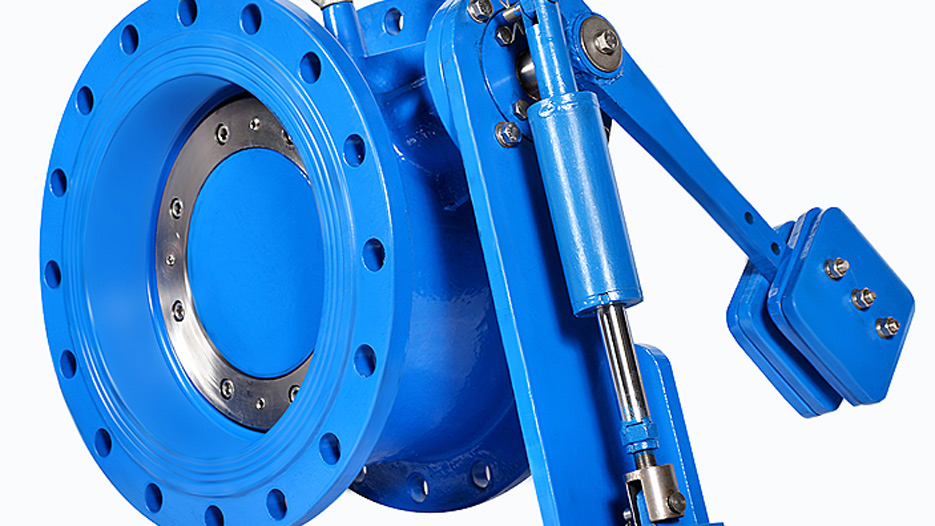

In the same year, we built our own foundry to produce all sorts of ductile iron pipes, fittings, manhole covers and gratings. The manhole covers are to the customer requirements; they can be light duty or heavy duty.

In 1999, we built the GRP pipe factory, which is producing GRP pipes and fittings. The GRP pipes are made from fibreglass. They are produced up to size 2600mm. In 2000, we built our own HDPE factory, which is the high-density polyethylene pipes with the new technology from one of the biggest and most famous companies in Germany.

In 2005, we started producing the pre-insulated pipes, which support the district cooling sections. Saudi Pipe Systems (SPS) has done a lot of big projects in Saudi Arabia for example King Abdul-Aziz University and King Abdullah Economic City, the Sea Port and King Faisal University and the Jeddah Corniche and also we did the Haram in Mecca expansion in Haram and Medina.

In addition, SPS has done many projects outside of the Kingdom for example in Sudan we have done many government projects. Now we are working on the international Cairo Airport project and we have done a lot of government projects in Yemen and some projects in Africa. We have also done the Saraya Aqaba project in Jordan. Further countries SPS is present are the UAE, Kuwait, Oman and Qatar.

Our strategy is to open a new market outside of the Kingdom and to expand and export products to Europe, Africa and the Far East. We are not going to depend on the Middle Eastern region only.

What makes you competitive?

We do have a lot of competition with China and India but our main target is quality. Our quality is much better than some other sources from China.

What are the innovation or quality programs that you have in order to make sure that your quality is much higher than the competition?

We care about having a lot of certifications in our company. We have the ISO certification and we have the NSF and the WRAS certifications. SPS has been approved by the Ministry of Water, Civil Defence and by the National Water Company, which is one of the biggest government companies in Saudi Arabia.

Are you currently the market leader?

We are one of the top ten companies in Saudi Arabia in our sector in the pipe, valve and fittings field. We are also leaders in fire hydrants.

What are your plans for 2016 and 2017 when it comes to technology or the diversification of your products?

We are now studying the possibility of building a new factory for a new technology that does not need a lot of labour; it is an automatic line that can work by itself so we can reduce the manpower expenses and at the same time increase the quality. It is going to happen in 2020. We hope that we will be one of the biggest leaders in the Middle East and beyond.

What are your main challenges that you face in doing business?

Cheap low quality products imported from China is one of our main challenges. As we have a lot of competition from these Chinese products, we will try to reduce our prices a little bit but our product have much higher in quality.

We are trying our best to make our factories as efficient and automatic as possible to reduce the labour costs so that we can reduce the price of our products in order to compete with the Chinese products.

Can you tell us more about the infrastructure development in Saudi Arabia?

In Saudi Arabia the country still needs a lot of infrastructure development. I think this is going to continue because so many projects are opening such as the metro. All of these projects need infrastructure so I don’t think the demand is going to stop.

When it comes to water pipes, we understand that the consumption of water will continue to increase. We hear that the main problem is the leakages that happen and that may trigger the replacement of the current pipes. This could foster well for your company.

Regarding the leakages, SPS is getting a new technology where instead of breaking the road, we can find where the leakage is exactly so we only have to open up in that place. There will be no need to break up the whole road as before to find out where a leakage is.

We have a new technology whereby we can cover the leak instead of changing the whole pipeline. Regarding the manhole covers and what we are producing: we face a lot of problems as the government complains that many people have fallen down manholes because there is no protection against this. We made a new solution and we put a net inside the manhole cover in case the cover is damaged. It means nobody can fall down. This has been approved by the National Water Company and the Ministry of Water.

Who are you biggest clients?

Our biggest client is the Ministry of Water and the National Water Company as well as all of the big contractors.