Pasqua Giuseppe: 50 years of quality aluminum and metal works for Ethiopian market

Sonia Pasqua, General Manager of Pasqua Giuseppe

Pasqua Giuseppe will be celebrating its 50th anniversary next year. Its segment is the metalwork; it manufactures aluminum and steel products and components. The company constructs everything from the canopy to the tankers underground. Pasqua was the first company in 2000 to receive the quality certification for the production of oil tankers and it has so far received multiple quality certifications from international giants like Shell and Total.

Interview with Sonia Pasqua, General Manager of Pasqua Giuseppe

Could you give us your overview of the economic development of Ethiopia and your outlook for 2014?

The ongoing development in Ethiopia is really substantial. There is a big market here and it is growing. The country has gone from a situation of extreme poverty to the government having a real plan that is pushing for development. The government is investing a lot into infrastructure which has really helped develop the private sector and is encouraging good economic development. I think that 2014 will be a good year as all companies are becoming more dynamic and are really qualifying all their work and their presentation and thus bringing better quality products to everyone. The private sector is working very well now.

Can you give us a brief history of the company?

Our company started business in 1965. Next year we will be celebrating our 50th anniversary. The company was established in the metalwork sector by my father. In the beginning it was more of a hobby for him. He was a building contractor and metalwork was his hobby. Later it became his main job and he stopped the building work. In the beginning, the products were mostly decorative artwork which you can still see in some places here. Later he moved into making building and agricultural products. He made agricultural products because the sector was doing particularly well and so he tried to make the most of the growing sector. He built the first trailers and water tankers for the water irrigation and transport systems. He also developed small bridges for the countryside and other steel structure developments. This is how he worked for a long time and how he worked through the more difficult political times of military government when there was very little private sector development, only some companies were able to continue working and ours was one of them.

After the new government came in, twenty years ago my brother and I came back after 13 years of work experience in Europe. We started to improve quality and offer new products to the market. The steel industry has a huge market in Ethiopia because there is so much progress going on. There is a lot of demand for steel in construction, agriculture, oil and gas etc. We started working with all of the oil companies who we targeted as our main clients. The majority of all the station canopies for all of the major oil companies in Ethiopia are manufactured by us. We construct everything from the canopy to the tankers underground. We are well qualified in this area and it is an area that has always interested us. We were the first company in 2000 to get the quality certification for the production of oil tankers. This has enabled us to be one of the major companies listed as an international supplier to be contacted for international tenders.

We were the first company in 2000 to get the quality certification for the production of oil tankers.

Can you tell us a bit more about your certificates and the quality of your products?

We have a variety of quality certifications. Four or five years ago we were awarded the distinction of being the best station canopy producer in Africa in terms of quality. This year we are experimenting with 5 new designs for station canopies for Total who have chosen us to produce their station canopies. We have also been certified for security in our workshops. We have received a quality certification from Total, and from Shell we received a certification that recognises us as providing excellent quality. We have also been awarded as best contractor for a station. We received a quality certification from the airport enterprise for the work we did on the VIP airport under a very short deadline. They considered our work to be of excellent quality especially considering the very short amount of time that we had. We also received great recognition for our work on the Gilgel Gibe dam which is one of the major hydroelectric dams under construction in Ethiopia. The dam was started in 1997 I believe and we were used to supply all of the steel gates. We were chosen as one of the certified project management companies due to the excellent quality application in our management system and our certified welders. This job was a great challenge for us but we were very happy to work on the project and we received a kind of medal that I keep on my desk.

What type of marketing strategy have you been using to gain more market share here and in the neighbouring countries?

Our main focus is on attracting the type of company and product that we want to work with. We have identified our target companies to be the oil companies. Therefore we try to supply them with the best quality products that they need. Our strategy is focused on providing the best quality. The oil companies demand top quality production, they are very sensitive about quality production especially when talking about oil tankers underground, because you don’t want to have any leakages. There is a lot of testing materials, production and quality to prevent leakages and we use all kinds of testing systems to guarantee quality.

Do you have any plans for expansion here in Ethiopia or possibly in other neighbouring countries?

Yes we are actually planning an expansion of production capacity. We have acquired new land on the industrial zone to be able to have more space and increase our production. We also want to start working with the neighbouring countries because they represent a very good market. We are already exporting abroad. We have a company that exports to Djibouti which is our neighbouring market. We also work with the oil companies in Djibouti, supplying steel structures and tankers. Therefore with this growing market we need to have a larger production space. In 2015 we will be celebrating 50 years in business and also the medium scale growth of our company. We are looking forward to this growth and we hope it will have a good impact on the oil and agricultural sectors. We want to develop a different kind of trailer as a new product for the agricultural sector. We want to make the most of the two main sectors that are developing in Ethiopia right now: oil and agriculture. We are sure that over the next 5 years both of these sectors will experience excellent growth.

What are the main challenges that your company faces at the moment?

Our market is growing a lot and the entire industry sector is growing so it can be hard to get enough qualified staff. This can be a challenge for us sometimes.

Can you tell us a bit about the work that you do with aluminium, particularly supplying the construction industry here in Ethiopia?

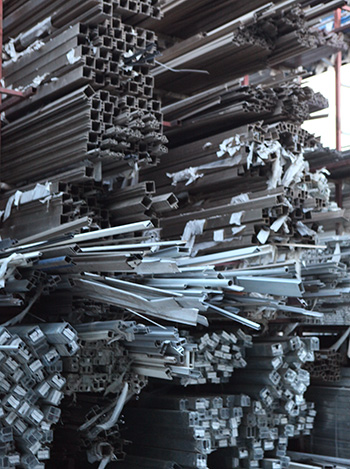

We are producing aluminium curtain wall cladding which is a new trend as we move towards more buildings with large, glass wall cladding structures. We were the first company to import and produce aluminium cladding in Ethiopia about 15 years ago. Until then it was only the large governmental buildings that were using aluminium and it was all imported, it was not manufactured or assembled here. We predicted that this would change and so we decided to import aluminium and the market now is really huge. There are more than 30 companies working with aluminium today. When we began it was a real challenge because the price of aluminium was three times that of steel. We had to present the differences between using the two materials. In the last 7 years the market has really grown. Although there are many companies selling aluminium, we are still working on all the major projects with clients who are looking for really high quality finishing and products. We have worked on some major buildings here which has allowed us to build up an excellent reputation for this kind of work. On some jobs we have worked in partnership, importing some technical expertise to mount some very important projects. We have also imported people from abroad to work on the sites.

Do you have to import the raw materials?

Do you have to import the raw materials?

Yes, we have to import them. We import all the aluminium because it is not manufactured here. The steel that we use is also imported. However we still manage to be competitive in the international market and we are able to export these products. Only lighter steel is produced in Ethiopia but that is not what we use in our products.

What other markets are you looking to penetrate besides Ethiopia?

We are mostly interested in the nearby markets. Sudan and South Sudan can both benefit from the same products that we are using in Ethiopia. There is also Djibouti which is another neighbouring country and we are also interested in the market in Saudi Arabia and Emirates. We have very competitive prices even though we import all the raw materials because our workforce costs are very low whilst the quality we produce is very high thus we can compete with big international companies.

What is your vision for Pasqua Giuseppe?

Our vision is to continue to have a good share of the local market and also to help our country strengthen its economy by exporting with a good export share. It´s an ambitious vision but I am sure we can do it.

FAIR USE POLICY

This material (including media content) may not be published, broadcasted, rewritten, or redistributed. However, linking directly to the page (including the source, i.e. Marcopolis.net) is permitted and encouraged.